Showroom

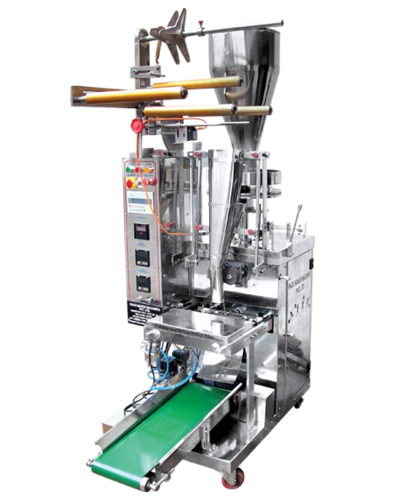

The Automatic Pouch Packing Machine is robust, efficient, and low-power, with computerized operation and automatic grade. Pneumatically powered, it packs from 10gm to 1kg with precision via a 4 Head Weigh Filler. It handles various materials, operating at speeds of 45 to 60 bags per minute, offering optional features like batch coding, cutting devices, auto lubrication, and gas flushing unit.

A Semi Automatic Pouch Packing Machine, within Multi-Function Packaging Machines, is robust, enduring, and energy-efficient. It operates semi-automatically, driven electrically with 1000W power consumption (800W for heating). Sealing at 13m/min, with a 15mm width and 0-300C temperature range, it handles up to 30kg conveyor load, with adjustable packing height (50-800mm).

Manual pouch packing machines, electrically driven, are heavy-duty multi-function packaging tools, known for durability and low power consumption. Unlike automated systems, they offer manual control for precise packaging. Robustly designed, they ensure reliable performance even in challenging conditions, allowing operators to adjust settings closely. Versatile and durable, they meet diverse packaging requirements, prioritizing manual control and endurance.

Liquid filling machines are semi-automatic tools for precise filling of free-flowing liquids into containers. With capacities ranging from 5 kg to 50 kg, they adapt to various needs. Rust-resistant and sturdy, they endure heavy-duty usage, consuming minimal power. Electrically driven, their semi-automatic operation allows manual control, ensuring reliable and efficient liquid filling across industries.

Robust filling machines accurately fill creams, gels, and sauces. Operating at 200V, 50/60Hz with 150W power, they're efficient and adaptable, handling various viscosities. With adjustable air pressure (0.4-0.6Mpa) and filling volumes from 10ml to 5000ml, optional 2-8 nozzles enhance productivity, filling 1000-1200 bottles/hour with speed and accuracy. Sturdy, ergonomic, and reliable, they meet diverse filling needs, emphasizing durability, efficiency, and precision across industries.

Packaging materials safeguard and present goods, with coding ink enabling clear labeling for identification. P.P. yarns provide durable strength for package security during transit. BOPP self-adhesive tapes ensure secure sealing, resisting tearing and moisture for reliability in shipping. These materials maintain package integrity, preserve product quality, and ensure safe delivery to consumers.

Granules powder filling machines efficiently dispense substances, operating at AC220V/110V with 180W power. They offer versatility with a range from 200g to 5kg and precision of 10g. Operating 5-10 times/min, crafted from 304 stainless steel, they ensure hygiene and longevity. Featuring foot pedal discharging, they enhance packaging efficiency and product quality.

A Cap Sealing Machine, with a single sealing head, moves left to right. Its electrical setup includes a 1 HP motor (415 Volts, 50 Hz) and a 300 Watt cap feeding bowl. The conveyor adapts to bottle and cap sizes (800-910mm), customizable to customer needs. Featuring low noise, torque adjustability, and computerized control, it ensures efficient, durable operation.

The Sticker Labelling Machine achieves speeds of up to 200 pcs/min with +-1% accuracy. Versatile, it accommodates bottles (20-100mm diameter, 30-200mm height) with labels up to 120mm tall and 20-300mm long. Rust-proof and durable, it operates efficiently with low power consumption. Its computerized system, automatic grade, and Human Machine Interface ensure seamless functionality, serving various labeling needs effectively.

Batch Coding Machines imprint crucial data on pouches, labels, and stickers, integrating smoothly into production lines. Their variable printing speed meets production needs, ensuring durability in industrial settings. Utilizing advanced printing, they provide clear and precise coding, facilitating accurate labeling and traceability for quality control and regulatory compliance across industries.

Box Strapping Machines automate package securing with straps, without computerization. They ensure efficiency via Frequency Speed Control, strapping at 2.3 seconds per strap. With automatic selection mode, they optimize operations. Robustly designed, weighing 185 kilograms, they prioritize durability, reliability, and secure packaging across industries, enhancing productivity and logistics efficiency.

Top Sealing Machines employ advanced technology for automatic product sealing, controlled by PLC systems. Pneumatically operated, they ensure efficiency and reliability, handling high-volume production with 1800 pieces per hour and accommodating 2 trays in one row. Constructed durably, they provide precise sealing, enhancing product freshness and shelf life, optimizing packaging processes for modern manufacturing environments.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free